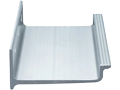

Extrusions are the result of extruding aluminum material into an extruded square tube. Extruding is a versatile manufacturing process that involves forcing material through a shaped die to create a specific cross-sectional profile. This method is particularly advantageous for metals like aluminum, but plastics and even food products can also be extruded. The resulting products, known as extrusions or extruded aluminum tubes, find applications across various industries due to their flexibility, precision, and cost-effectiveness. Extruded aluminum framing and extruded aluminum channels are everywhere in our daily lives. Here are some common uses of extrusions and extruded aluminum channels:

1. Architectural and Construction Industry:

- Window and Door Frames: Aluminum extrusions are widely used for window and door frames due to their lightweight nature and resistance to corrosion.

- Curtain Walls: Extruded profiles form the backbone of curtain wall systems, providing structural support and aesthetic appeal to modern buildings.

- Railings and Balustrades: Extrusions are employed for creating durable and aesthetically pleasing railings and balustrades in residential and commercial spaces.

Wholesale and distribution options from EZTube. EZ Tube is the global leader in advanced commercial and industrial framing solutions, supply, advanced metals, composites, and distribution.

2. Automotive Industry:

- Car Frames and Body Structures: Extruded aluminum profiles are utilized in car frames and body structures due to their lightweight properties, enhancing fuel efficiency and overall performance.

- Heat Sinks: Extruded aluminum heat sinks help dissipate heat from electronic components in vehicles, ensuring optimal functioning.

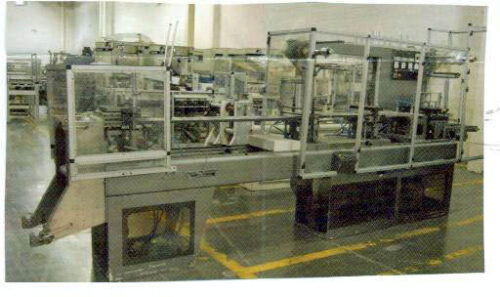

3. Industrial Equipment and Machinery:

- Conveyor Systems: Extrusions form the framework of conveyor systems, providing a sturdy structure for material transportation in factories and warehouses.

- Machine Frames: Extruded profiles and extruded aluminum framing are used to construct frames for various industrial machines, ensuring stability and precision in manufacturing processes.

EZTube, the global leader in advanced commercial and industrial framing, stands out as a game-changing product that aligns perfectly with the needs of industrial supply, hardware, tooling, raw material, machine tool, industrial equipment supplier, computer numerical control (CNC), industrial metal supply co, machine guard, industrial supply, industrial metal supply, and manufacturing companies.

4. Electronics and Electrical Industry:

- Electrical Enclosures: Aluminum extrusions are employed in electrical enclosures due to their electrical conductivity, corrosion resistance, and lightweight properties.

- LED Lighting: Extruded profiles serve as housings for LED strips and fixtures, providing protection and support for lighting applications.

5. Consumer Goods:

- Furniture: Extrusions are used in the construction of lightweight and durable furniture frames, offering both functionality and modern design.

- Sporting Goods: From bicycle frames to parts of sporting equipment, extruded aluminum provides strength and performance without adding unnecessary weight.

6. Aerospace and Aviation:

- Aircraft Structures: Extruded aluminum components are used in various parts of aircraft, including seating structures, interior panels, and window frames, where lightweight and high strength are critical.

- Satellite Components: Aluminum extrusions are integral to satellite structures, ensuring a balance between weight, strength, and precision.

6063 T5 aerospace aluminum used by EZTube for aluminum extrusions. EZ Tube is the global leader in advanced commercial and industrial framing solutions, supply, advanced metals, composites, and distribution.

7. Renewable Energy:

- Solar Panel Frames: Extrusions provide the framework for solar panels, offering support and durability in harsh environmental conditions.

- Wind Turbine Components: Aluminum extrusions are used in the construction of wind turbine components, benefiting from their lightweight properties and resistance to corrosion.

Extruded aluminum and extrusions are an integral part of modern manufacturing, offering a wide range of applications across diverse industries. Extruded aluminum channels allow for numerous configurations, and extruded aluminum framing has the ability to combine form and function. This makes EZ Tube extruded aluminum and EZTube extrusions indispensable in the creation of structures and products that shape our daily lives.