Linear Rail Extrusions: Uses and Benefits

Linear rail extrusions are essential components in the world of precision engineering, automation, and machinery. They provide a smooth, reliable, and precise means of linear motion, which is critical in various applications, from 3D printing to CNC machining. This article explores what linear rail extrusions are, their types, uses, and benefits.

What Are Linear Rail Extrusions?

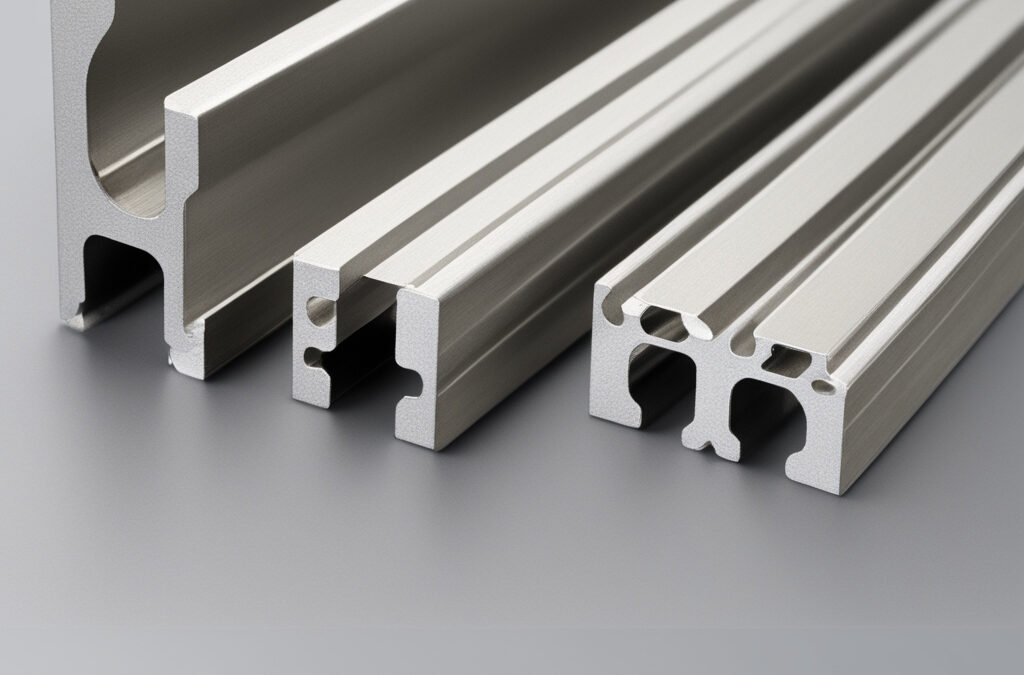

Linear rail extrusions are mechanical components used to guide and support linear motion. They consist of a rail and a carriage (or block) that moves along the rail. The rail is typically made of a high-strength, corrosion-resistant material like aluminum or steel, while the carriage often contains ball bearings or rollers to reduce friction and ensure smooth movement.

How are Linear Rail Extrusions Manufactured?

Types of Linear Rail Extrusions

There are several types of linear rail extrusions, each suited to specific applications and load requirements:

- Profiled Rail Guides:

- Rectangular Rails: These have a rectangular cross-section and are known for their high load-bearing capacity and rigidity. They are commonly used in heavy-duty applications.

- Square Rails: Similar to rectangular rails but with a square cross-section, offering good load distribution and high precision.

- Round Rail Guides:

- Round Shaft Guides: Featuring a cylindrical shape, these rails are typically less expensive and easier to install but may not offer the same precision as profiled rails.

- Miniature Linear Guides:

- Designed for small-scale applications, these guides are used in devices where space is limited, such as in compact medical devices or small-scale automation systems.

- Dovetail Slides:

- These guides use a dovetail-shaped groove for the carriage to slide in. They provide high rigidity and are often used in applications requiring precise positioning.

Applications of Linear Rail Extrusions

Linear rail extrusions are used across a wide range of industries due to their versatility and precision. Some common applications include:

- CNC Machines:

- Linear rails provide the necessary precision and rigidity for the accurate movement of cutting tools and workpieces.

- 3D Printers:

- They ensure smooth and precise movement of the print head, leading to high-quality prints.

- Robotics:

- Linear rails are used in robotic arms and automated systems to enable precise and repeatable movements.

- Medical Equipment:

- They are used in diagnostic devices and surgical robots where precision and reliability are crucial.

- Automotive Industry:

- Linear rails are used in various stages of car manufacturing, including assembly lines and quality control systems.

Benefits of Linear Rail Extrusions

- High Precision:

- Linear rails offer exceptional accuracy, essential for applications requiring precise movements.

- Load Capacity:

- They can support significant loads, making them suitable for heavy-duty applications.

- Durability:

- Made from robust materials, linear rails are designed to withstand harsh operating conditions and long-term use.

- Smooth Movement:

- The use of ball bearings or rollers in the carriage ensures minimal friction, resulting in smooth and consistent movement.

- Versatility:

- Available in various sizes and configurations, linear rails can be tailored to fit a wide range of applications.

Where to buy linear rail extrusions?

Linear rail extrusions are integral to the functionality of many modern machines and devices. Their ability to provide precise, reliable, and smooth linear motion makes them indispensable in industries ranging from manufacturing to healthcare. Understanding the types and applications of linear rail extrusions can help in selecting the right component for a specific need, ensuring optimal performance and efficiency.

EZTube is the premier global supplier in advanced construction systems, framing solutions, and linear rail extrusions

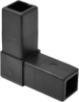

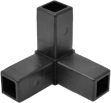

Linear rail extrusions, available from 1 inch to larger dimensions like 4×4, are a versatile and indispensable material in construction and industrial applications. Whether you need robust steel tubing or lightweight aluminum options, there’s a variant to meet your project’s needs. Be sure to choose the right connectors and fittings to ensure a strong and reliable assembly.

For more information on specific products and pricing, shop at trusted global suppliers like EZTube, which offers a wide range of squares, fittings, fasteners, and related accessories to bring your projects to life.