EZTube, the leading global supplier of advanced commercial and industrial solutions, recognizes the importance of seamless connections, and one of the key components contributing to this efficiency is press fittings.

In this article, you’ll learn about press fittings; exploring what they are, their advantages, and how EZTube incorporates them into its offerings for a diverse range of industrial applications.

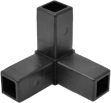

5-Way Composite Press Fit Connector by EZTube

Understanding Press Fittings: A Revolution in Connection Technology and Champion of Industrial Design

EZ Tube Hammer Fit press fittings and connectors offer a modern and efficient method of joining pipes and tubing without the need for welding or soldering. The process involves using a specialized tool to compress a fitting onto the tubing, creating a secure and leak-proof connection. This technology has gained popularity for its speed, reliability, cost-savings, and versatility across various industries.

Advantages of Press Fittings: Redefining Efficient Construction

Time-Saving Installation

Press fittings eliminate the need for time-consuming welding or soldering processes. The connection is made by simply pressing the fitting onto the tubing, significantly reducing installation time. This is particularly advantageous in fast-paced industrial settings where time efficiency is a critical factor.

Consistent Quality

The EZTube press fitting connector process ensures a consistent and reliable connection every time. The uniform compression of the fitting onto the tubing results in a tight seal, minimizing the risk of leaks and ensuring the structural integrity of the joint.

Versatility Across Materials

EZ Tube press fittings and connectors are compatible with a variety of materials, including steel, stainless steel and aluminum tubing, adding to their versatility. This compatibility allows for the creation of diverse structures and systems with ease.

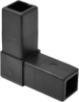

Advanced Composite or Welded Steel Core

You choose what works best for your application. EZTube offers a full range of nylon injection-molded, high-strength composite press-fit connectors and ABS nylon coated welded steel core connectors.

EZTube’s Integration of Connectors and Press Fittings: Precision with Reliability

Steel, Stainless Steel, and Aluminum Options:

EZ Tube understands the diverse needs of its customers and offers press fittings suitable for both stainless steel and aluminum tubing. This flexibility allows users to choose the material that best suits the requirements of their specific industrial applications.

Customization and Compatibility:

EZ Tube’s connectors and press fittings are designed with customization in mind. They seamlessly integrate with the company’s modular framing systems, offering users the ability to create tailored structures with precision and ease.

Efficient Assembly for Modular Frames:

Press fittings play a crucial role in the assembly of EZTube’s modular frames. Whether constructing workstations, displays, racks, or industrial automation systems, the efficiency of connectors and press fittings contributes to the overall speed and reliability of the assembly process.

Ensuring Safety and Compliance: Quality Assurance

Rigorous Testing

EZTube places a strong emphasis on quality assurance. Connector press fittings undergo rigorous testing to ensure they meet industry standards for strength, durability, and leak resistance. This commitment to quality provides customers with confidence in the reliability of their industrial systems.

Compliance with Industry Standards

EZTube’s press fit connectors comply with industry standards, ensuring that they meet the stringent requirements of various applications, including those in construction, manufacturing, and automation.

Restaurant using EZTube framing to build bars, tables, booths, lighting fixtures, storage racks, shelves, refrigerator organizers, coat racks, menu frames, and more.

Press fittings represent a paradigm shift in connection technology

EZTube’s incorporation of this efficient and reliable method into its industrial solutions reflects a commitment to providing cutting-edge solutions for its customers. From time-saving installations to consistent quality and compatibility with various materials, press fittings are a cornerstone of EZTube’s efforts to streamline industrial processes and empower users to create robust and efficient structures. The seamless connections facilitated by press fittings will undoubtedly play a pivotal role in shaping the future of industrial applications.