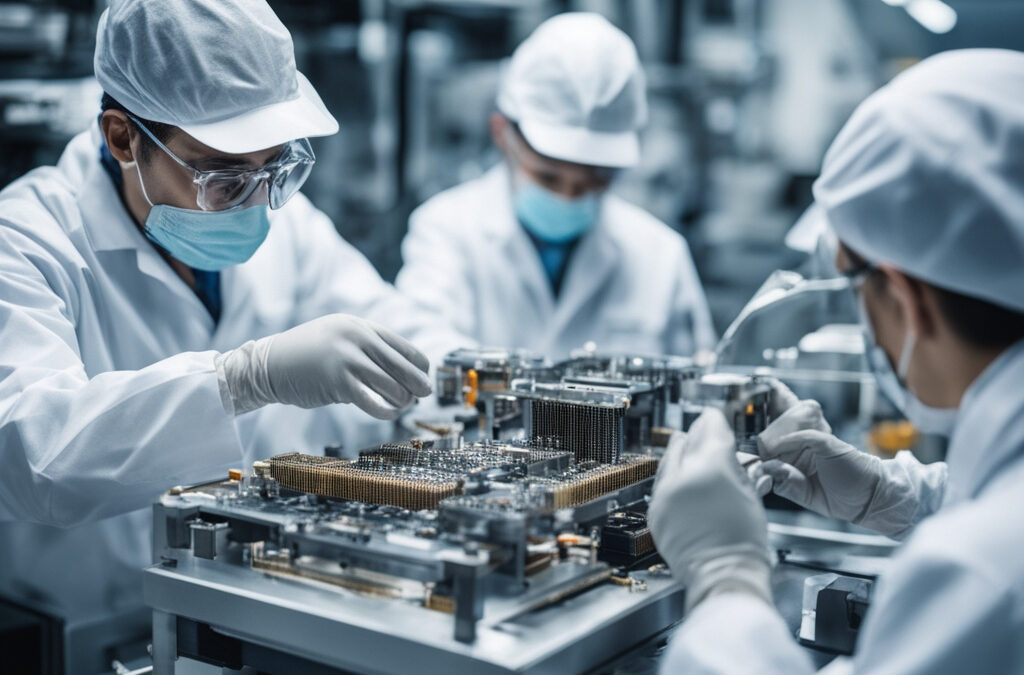

Semiconductor manufacturers and the semiconductor industry, both pillars of modern technology, relies heavily on the materials used in its manufacturing processes. As with each manufacturing industry, the selection of advanced, aerospace-grade materials like 6063 T5 aluminum, steel, stainless steel, and composites plays a crucial role in advancing semiconductor manufacturing by enhancing efficiency, precision, and sustainability. These materials offer unique properties that cater to the stringent demands of the industry, contributing to the production of smaller, faster, and more powerful devices.

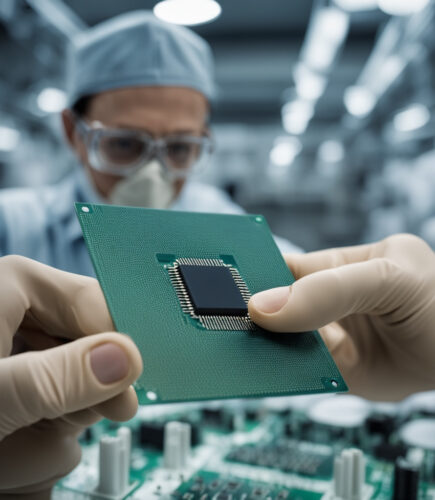

Precision CNC machining by EZ Tube for advanced semiconductor manufacturing.

Aluminum: Lightweight and Conductive

Aluminum is a preferred material in semiconductor manufacturing due to its lightweight nature and excellent thermal and electrical conductivity. In cleanroom environments, where contamination control is paramount, aluminum’s non-corrosive properties ensure that it doesn’t degrade or emit particles that could compromise the delicate semiconductor fabrication processes. Aluminum is often used in the construction of cleanroom walls, frames, and enclosures, providing a durable yet lightweight solution that supports the industry’s need for precision and cleanliness.

In addition to structural applications, aluminum is also used in heat sinks and other thermal management components within semiconductor manufacturing equipment. Its ability to efficiently dissipate heat helps maintain optimal operating temperatures for equipment, reducing the risk of overheating and ensuring consistent production quality.

A system-on-chip (SoC) in production

Steel: Strength and Durability

Steel, known for its strength and durability, is indispensable in the semiconductor manufacturing process. It is commonly used in the construction of robust manufacturing equipment and support structures that must withstand the rigors of continuous operation. The high tensile strength of steel ensures that it can handle the mechanical stresses involved in the fabrication and assembly of semiconductor devices.

Moreover, steel’s versatility allows it to be used in various forms, such as steel tubes, frames, and connectors, which are essential for the modular construction of semiconductor manufacturing facilities. The ability to create modular structures with steel enables manufacturers to easily reconfigure and expand their operations, adapting to the ever-changing demands of the semiconductor market.

Stainless Steel: Corrosion Resistance and Cleanliness

Stainless steel is particularly valued in semiconductor manufacturing for its corrosion resistance and ability to maintain cleanliness. The stringent cleanliness standards in semiconductor fabrication necessitate the use of materials that do not corrode or degrade over time, as even the smallest contaminants can affect the quality of semiconductor wafers.

Stainless steel is widely used in cleanroom furniture, chemical processing equipment, and gas delivery systems due to its non-reactive nature. Its resistance to corrosion ensures that it does not introduce contaminants into the manufacturing environment, thereby preserving the integrity of the semiconductor production process.

A semiconductor on a circuit board

Composite Materials: Innovation and Adaptability

Composite materials are increasingly being adopted in semiconductor manufacturing due to their innovative properties, such as high strength-to-weight ratios, thermal stability, and chemical resistance. These materials can be engineered to meet specific performance criteria, making them ideal for specialized applications within the semiconductor industry.

For instance, composite materials are used in the construction of lightweight, high-strength components for semiconductor processing equipment. Their ability to withstand harsh chemical environments and extreme temperatures makes them suitable for use in plasma etching chambers and chemical vapor deposition (CVD) reactors, where traditional materials might fail.

Moreover, composites can be designed with tailored properties to reduce electromagnetic interference (EMI), a critical factor in maintaining the precision and accuracy of semiconductor manufacturing processes.

Advanced processes facilitated by aluminum, titanium, and advanced ceramics

The advancement of semiconductor manufacturing relies heavily on the strategic use of materials like aluminum, steel, stainless steel, and composites. Each of these materials brings unique benefits to the industry, from aluminum’s lightweight conductivity to the strength of steel, the cleanliness of stainless steel, and the adaptability of composites. Together, they enable the production of increasingly sophisticated devices, driving innovation in technology and shaping the future of electronics. EZTube, a trusted global supplier of advanced metals, ceramics, and advanced materials, is at the forefront of supplying these manufacturers with the materials they need to further technological progress.