What are aluminum tube framing systems, and how are they used in construction, design, manufacturing, and more?

Aluminum tube framing systems are a revolutionary solution that empowers builders, architects, industrial suppliers, manufacturers, and DIY enthusiasts of all sorts to unleash their creativity and bring their visions to life with unparalleled ease and precision. Explore the applications of aluminum tube framing systems, and delve into the key components and techniques that make them indispensable in a wide range of projects.

Understanding Aluminum Tube Framing Systems

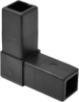

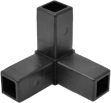

Aluminum tube framing systems offer a versatile and modular approach to construction, allowing for the quick and easy assembly of structures ranging from industrial workstations to custom machinery frames. At the heart of these systems are aluminum tubing connectors, which enable seamless integration and assembly of extruded aluminum tubes. EZ Tube exclusively uses 6063 T5 grade aluminum for its extrusions and extruded aluminum tubing, which is aerospace grade and renowned as the best aluminum alloy in the industry.

This is just one reason amongst countless others why EZ Tube is the very best in extruded aluminum tubes.

Museum signs and sign frames built using EZTube, the leading global supplier of advanced commercial and industrial framing solutions

Key Features and Benefits

- Versatility: With a wide range of aluminum tubing connectors available—including 1 square tubing connectors, 2 inch square tubing connectors, and 3/4 inch square tubing connectors—aluminum tube framing systems offer unparalleled versatility in design and configuration. From simple shelving units to complex machinery frames, the possibilities are endless.

- Durability: Aluminum square tubes are renowned for their durability and strength-to-weight ratio. Constructed from high-quality aluminum extrusions, these systems offer exceptional structural integrity while remaining lightweight and easy to handle.

- Modularity: One of the standout features of aluminum tube framing systems is their modular design. Components can be easily disassembled and reconfigured to accommodate changing needs and requirements, making them ideal for dynamic environments where flexibility is key.

- Ease of Assembly: Thanks to innovative press-fit framing techniques, assembly of extruded aluminum tubes is quick and straightforward. No welding or specialized tools are required, allowing for rapid construction and installation with minimal effort.

- Customization: Aluminum tubes and injection mold fittings offer limitless customization options, with a wide range of accessories and components available to tailor structures to specific requirements. From brackets and fittings to extruded aluminum tracks, the possibilities for customization are virtually endless.

Applications of Aluminum Tube Framing Systems

- Industrial Workstations and Tool Carts: Create customized workstations and tool carts tailored to specific workflow and ergonomic needs.

- Custom Machinery Frames: Construct robust and reliable frames for machinery, equipment, and automation systems with ease.

- Modular Shelving and Storage Solutions: Design versatile shelving units and storage racks that can adapt to changing inventory requirements and space constraints.

- Exhibition Booths and Displays: Build eye-catching exhibition booths and displays that stand out from the crowd while offering easy assembly and transportability.

Where to buy extruded aluminum tubes?

Aluminum tube framing systems represent a revolution in construction and design, offering unparalleled versatility, durability, and ease of assembly. Whether you’re a seasoned professional or a DIY enthusiast, these systems empower you to bring your creative visions to life with precision and efficiency. All that’s left now is to buy your aluminum tube framing system, but where to buy alumium extrusions and metal tubing? Shop individual or wholesale extruded aluminum tubes today from EZTube or from an EZ Tube wholesale partner. Experience the endless possibilities of aluminum extrusions today!