Breakthrough practices in manufacturing result in massive gains for consumers

What is lean methodology? Lean methodology, inspired by the renowned Toyota Production System, has emerged as a powerful framework for streamlining processes, eliminating waste, and optimizing productivity. When applied to the aluminum extrusion process, lean principles can unlock significant improvements in efficiency, quality, and profitability. In this blog post, we’ll explore how manufacturers can harness the power of lean methodology to enhance their aluminum extrusion operations.

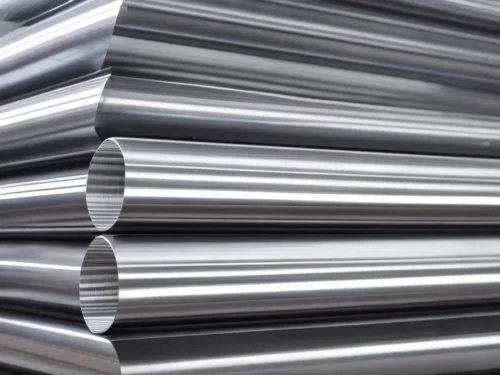

6063 T5 extruded aluminum tube

Identify Value Streams

The first step in implementing lean methodology in aluminum extrusion is to identify and map out the value streams within the process. Value stream mapping involves analyzing each step of the extrusion process, from raw material input to finished product output, to identify areas of waste, inefficiency, and opportunity for improvement. By gaining a comprehensive understanding of the value streams, manufacturers can pinpoint areas where lean principles can be applied to maximize efficiency and add value for customers.

Eliminate Waste

Lean methodology emphasizes the elimination of waste in all its forms, including overproduction, excess inventory, unnecessary motion, defects, and waiting time. In the aluminum extrusion process, waste can manifest in various ways, such as inefficient material handling, setup times, or non-value-added operations. By systematically identifying and eliminating waste, manufacturers can streamline the extrusion process, reduce lead times, and minimize costs while enhancing overall quality and customer satisfaction.

Implement Continuous Flow

Another core principle of lean methodology is the concept of continuous flow, which aims to create a smooth, uninterrupted flow of materials and information throughout the production process. In the context of aluminum extrusion, implementing continuous flow involves optimizing production layouts, minimizing batch sizes, and synchronizing operations to achieve a steady and consistent workflow. By eliminating bottlenecks and interruptions, manufacturers can enhance throughput, reduce cycle times, and improve overall efficiency.

Empower Employees

Central to the success of lean methodology is the involvement and empowerment of employees at all levels of the organization. By fostering a culture of continuous improvement and providing employees with the tools, training, and autonomy to identify and address issues, manufacturers can tap into the collective knowledge and creativity of their workforce to drive meaningful change. Engaging employees in the lean journey not only leads to more sustainable improvements but also fosters a sense of ownership and pride in the manufacturing process.

Embrace Kaizen

Kaizen, or continuous improvement, lies at the heart of lean methodology. Encouraging small, incremental improvements on a daily basis can yield significant long-term benefits in terms of efficiency, quality, and customer satisfaction. In the context of aluminum extrusion, implementing kaizen involves empowering employees to identify and implement improvements in their respective areas of expertise, whether it be optimizing machine settings, reducing scrap, or streamlining workflow processes. By embracing kaizen as a core principle, manufacturers can foster a culture of innovation and excellence that drives continuous growth and success.

Where to buy aluminum extrusion produced through lean methodology?

EZ Tube is the leading supplier of advanced commercial and industrial framing. With a strong supply chain enabled through lean methodology, EZTube is your one-stop shop for all aluminum, steel, 304 stainless steel, advanced composite, injection mold plastics, aluminium, heavy equipment, and industrial hardware supply needs. Buy EZ Tube, connectors for square tube, and square tube framing online or through a leading distributor of premium EZ Tube products.

Aerospace-grade 6063 extruded aluminum exclusively used by EZTube

In an increasingly competitive marketplace, the adoption of lean methodology is essential for manufacturers seeking to stay ahead of the curve. By applying lean principles to the aluminum extrusion process, manufacturers can unlock significant improvements in efficiency, quality, and profitability while delivering greater value to customers. By identifying value streams, eliminating waste, implementing continuous flow, empowering employees, and embracing kaizen, manufacturers can transform their extrusion operations into lean, agile, and highly efficient processes that drive sustainable growth and success.